which of the following is a type of machine safeguarding punching

Nip guard to in-running rolls and fixed railing or fencing to engines motors planning or shaping machine are of this type. The 5 most common ways of machine guarding.

A good machine safeguarding system eliminates the possibility of the operator or another worker placing parts of their bodies near hazardous moving parts.

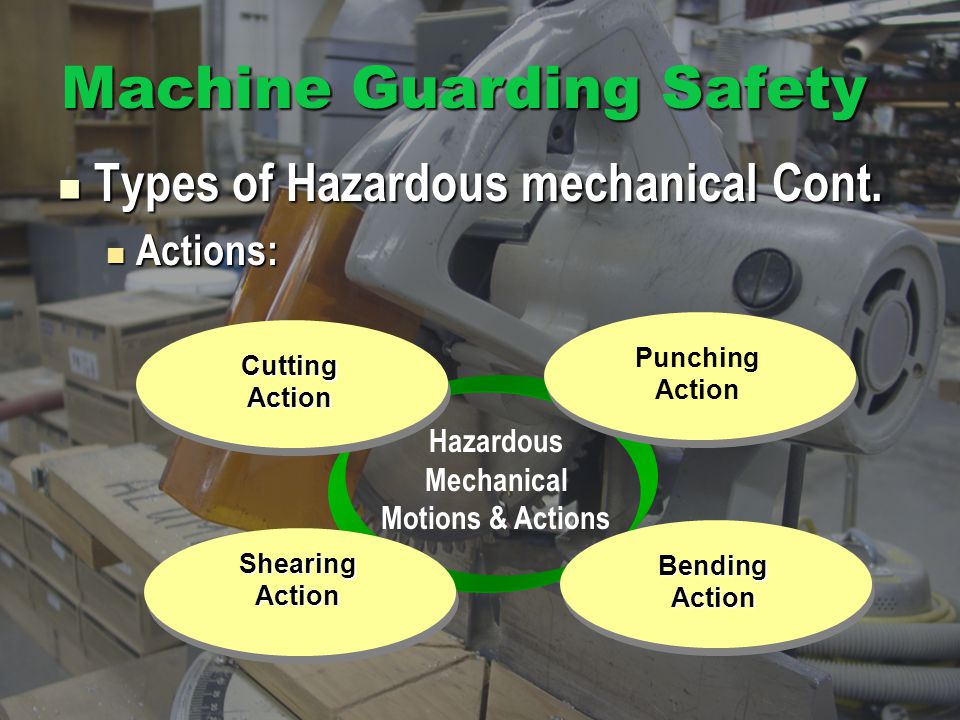

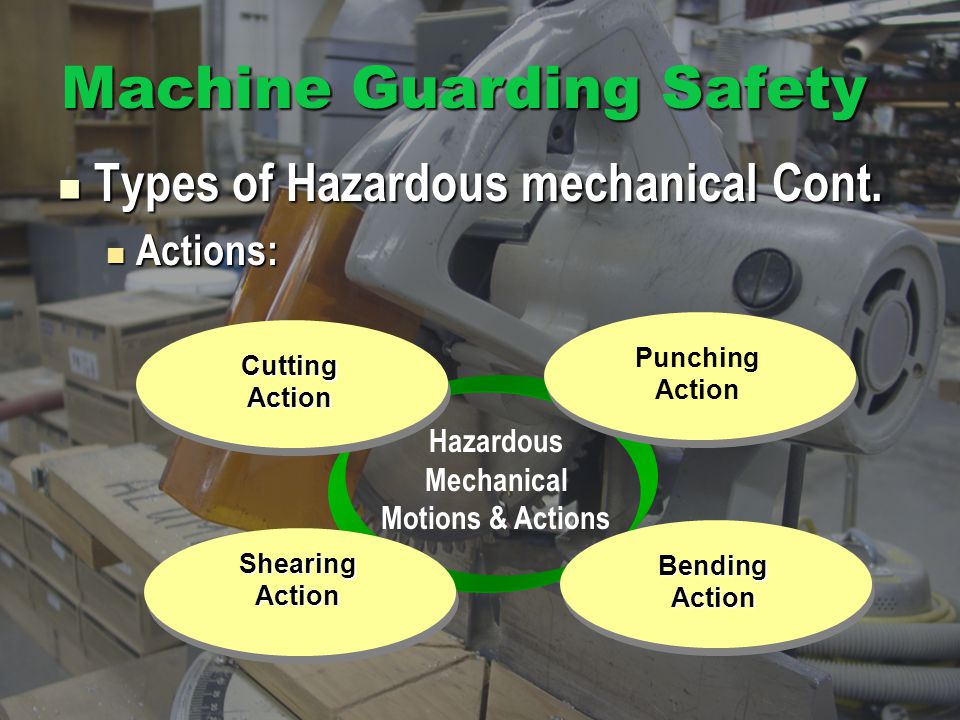

. These different types of hazardous mechanical motions and actions are basic in varying combinations to nearly all machines and recognizing them is the first step toward protecting operators from the danger they present. Machine guards are your first line of defense. It may stop the machine if a hand or any part of the body is inadvertently placed in the danger area.

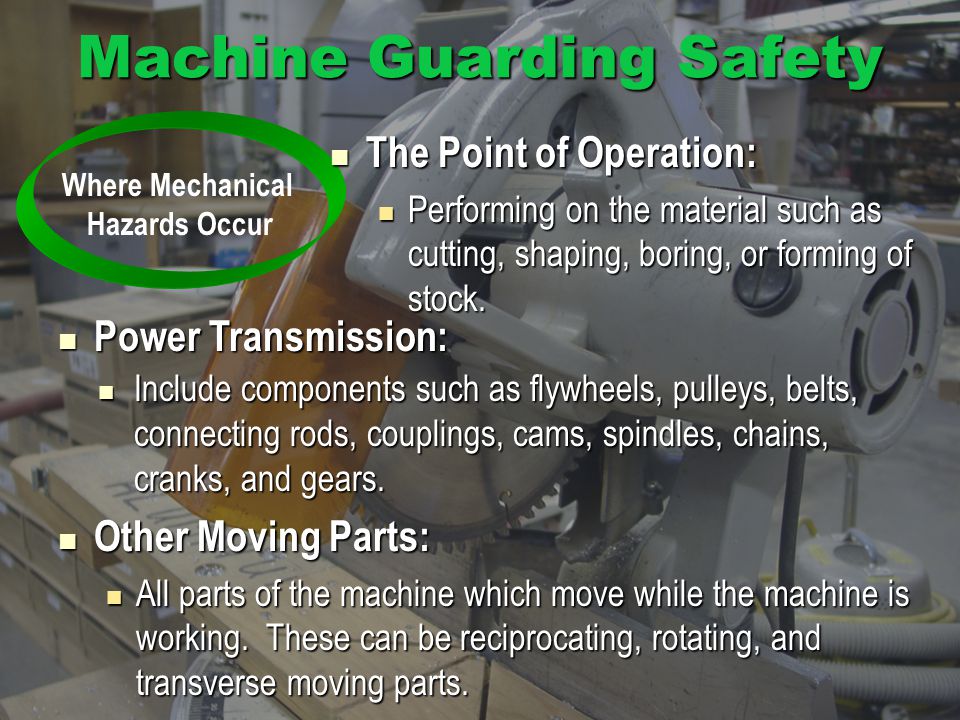

The danger of this type of action occurs at the point of operation where stock is inserted held and withdrawn by hand. Any machine part function or process that may cause injury must be safeguarded. A Punching B Feeding and Ejection methods C Poinit of operation D In-going nip points Question.

The machine tool is heavy and rigid designed for removing. In this regard is punching a type of machine safeguarding. Punching action results when power is applied to a slide ram for the purpose of blanking drawing or stamping metal or other materials.

Moving machine parts have the potential to cause severe workplace injuries such as crushed fingers or hands amputations burns or blindness. This problem has been solved. Pullback devices utilize a series of cables attached to the operators hands wrists andor arms and are primarily used on machines with stroking action.

Which of the following is an exception to the general rule for safeguarding to prevent hazards during servicing and maintenance of machines. Interlock guards make certain that the machine cannot be started until the guard screen is in the closed position and conversely the guard cannot be removed until the working parts have been stopped. Workers should not be able to easily remove or tamper with the machine guard because a machine guard that can easily be made ineffective is no machine guard at all.

Must prevent workers from lubricating a machine without removing the safeguard Which of the following should employers prevent in order to ensure the safety and health of workers in regards to machine guarding. Primary Safeguarding Methods Two primary methods are used to safeguard machines. When the operation of a machine or.

Any machine part function or process that may cause injury must be safeguarded. Machines can cause a variety of injuries ranging from minor abrasions burns or cuts to severe injuries such as fractures lacerations crushing injuries or even amputation. Which of the following is a type of machine safeguarding.

The employer shall provide and ensure the use of properly applied and adjusted point of operation devices or guards for every operation performed on a. Machines with moving parts present many potential hazards to workers who operate them. Pull outs Restraints.

Which of the following is an exception to the general rule for safeguarding to prevent hazards during servicing and maintenance of machines. The following stated below are the types of slotting machine and their working. Each piece of machinery has its own unique mechanical and non-mechanical hazards.

Servicing or maintenance is not hazardous for employees b Maintenance is minimal and performed as an important part of production c Employer uses other safeguards which provide effective protection as required. This problem has been solved. Any part of a machine which ___ while in operation can cause a hazard.

Mechanical Engineering questions and answers. Methods of Safeguarding They can be fixed interlocked adjustable or self-adjusting. Crushed fingers or hands amputations burns and blindness are just some of the potential hazards that can occur when a machine guarding is not properly installed.

Devices these limit or prevent access to the hazardous area. B Maintenance is minimal and. 29 CFR 1910212 a 1 states that one or more methods of machine guarding must be used to protect operators and other employees from hazards including those created by point of operation in-running nip.

A Servicing or maintenance is not hazardous for employees. Which of the following is a type of machine safeguarding. Typical machines used for punching operations are power presses and ironworker machines.

The most common types of machine guards are. Rotating including in-running nip points. Similarly what are the 2 types of primary safeguarding methods.

O Punching O Feeding and ejection methods O Point of operation O In-going nip points. It and is used for cylindrical objects involving operations like seaming flanging embossing riveting and punching. Safeguards are essential for protecting workers from these preventable injuries.

Electromechanical sensing device on eye-letter machine. The basic types of hazardous mechanical motions and actions are. These can include the movement of rotating members reciprocating arms moving belts meshing gears cutting teeth.

These can be presence-sensing devices pullback or restraint straps safety trip controls two-hand controls or gates. Also know what are the most common types of machine guarding. When the slideram is up the operator is allowed access to the point of operation.

4206 SAFEGUARDING THE POINT OF OPERATION. Typical machines used for punching operations are power. Which of the following is a type of machine safeguarding punchink feeding and ejection methods point of operation in-going nip points Feeding and ejection methods is a.

Two Hand controls Two hand Trip. One may also ask is punching a type of machine safeguarding. The following are all machine safeguarding requirements except.

Which of the following is a type of machine safeguarding.

Chapter 1 Basics Of Machine Safeguarding

Chapter 1 Basics Of Machine Safeguarding

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Basics Of Machine Guarding Hazards And Solutions March

Machine Guarding Safety Cfr Ppt Download

Machine Guarding Safety Cfr Ppt Download

Oshacademy Course 154 Machine Safeguarding Basic Module 2

Which Of The Following Is A Type Of Machine Safeguarding A Punching B Feeding And Ejection Brainly Com

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Chapter 1 Basics Of Machine Safeguarding

Chapter 1 Basics Of Machine Safeguarding